Overview

DSH Station: Your One-Stop Solution for Accurate Temperature Control

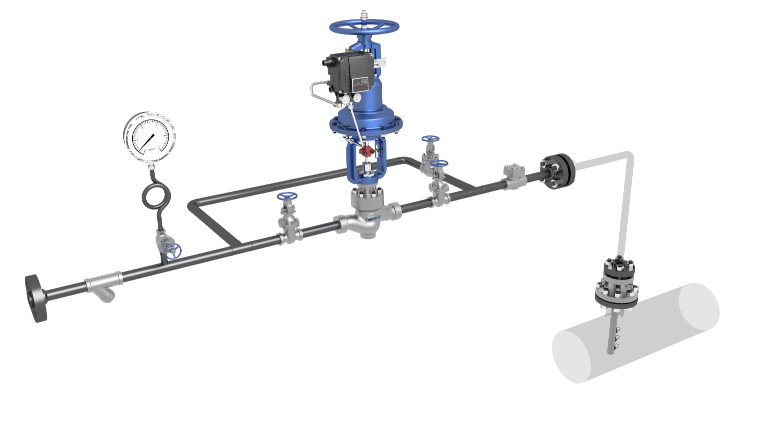

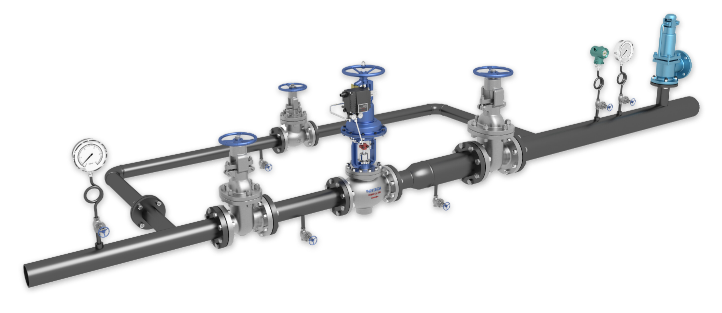

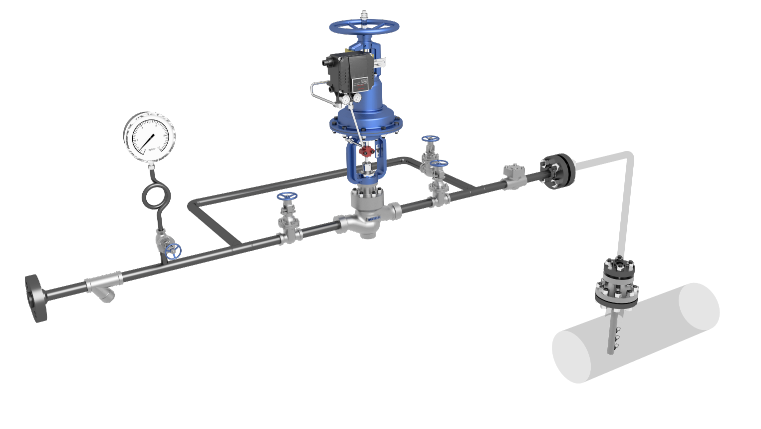

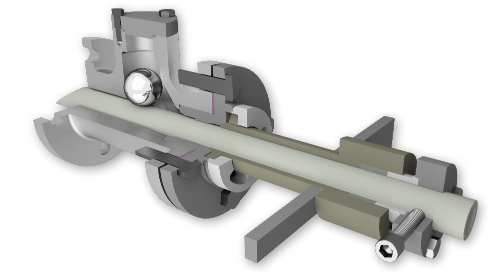

The Desuperheating Station (DSH) regulates the steam temperature by injecting atomised water into the steam flow, thereby gently reducing the temperature to the desired set point.

IndiTech’s DSH Station is a powerful tool for industrial processes that require precise control of steam temperature. The benefits extend far beyond temperature control. By ensuring optimal steam conditions it helps to:

- Protect vital equipment: High-temperature steam can damage sensitive equipment, leading to costly downtime and repairs. IndiTech’s DSH Station safeguards your investments by maintaining safe operating temperatures.

- Enhance product quality: Many industrial processes require specific steam temperature conditions for optimal product quality. IndiTech’s DSH Station ensures consistent temperature, leading to superior results.

- Boost efficiency: Precise steam temperature control optimises energy consumption, minimising waste and reducing operating costs.

With its easy installation, minimal maintenance requirements, and reliable performance, the IndiTech DSH Station is an indispensable tool for any industry that relies on steam to power its operations.

Enjoy precise steam temperature control and worry-free operation with IndiTech’s advanced range of DSH Stations.

Application

Steam temperature reduction

The Desuperheating Station is used in multiple industrial processes to reduce the temperature of steam to the desired level.

Technical Data

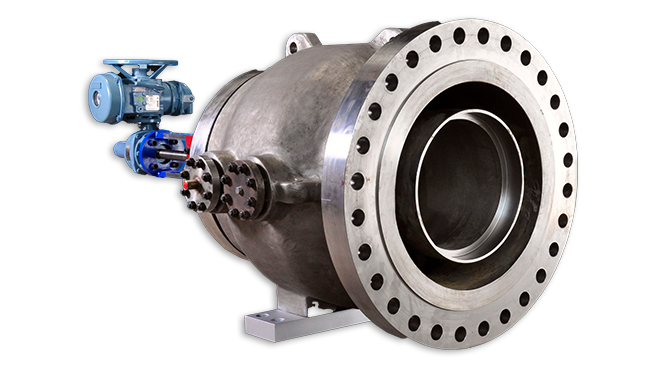

STEAM PIPE SIZE

NPS 1 to NPS 80 (DN25 to DN2000)

PRESSURE RATING

CL150 to CL2500

PIPING MATERIAL

A106 Gr. B; A335 P11/P22/P91

END CONNECTIONS

Flanged/Socket Weld/Butt Weld

CONFIGURATION

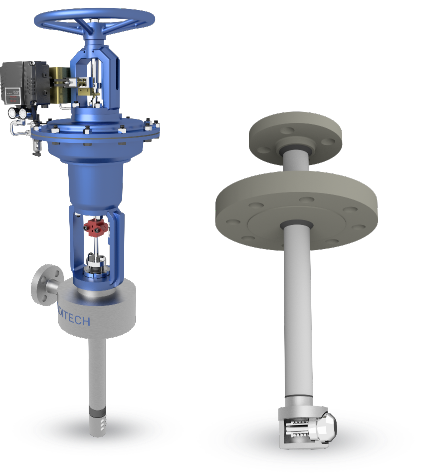

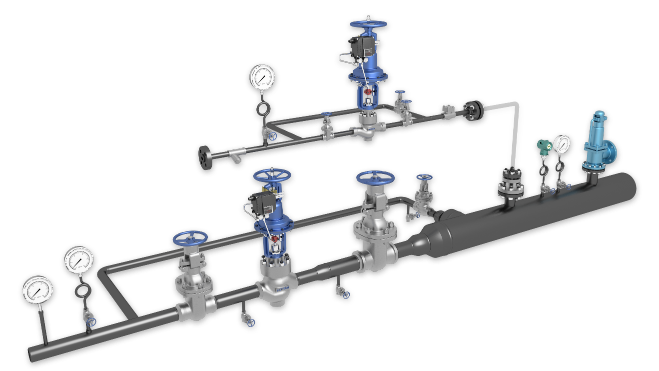

Separate TCV & DSH/

Combined TCV+DSH

ACCESSORIES

- Flow Meters

- Control Panels (PID controller-based/PLC-based)

- Strainers

- Steam Trap Module

- Piping Supports

- Base Frame Skid

Features

- Modular Ready-to-Fit temperature-reducing solution

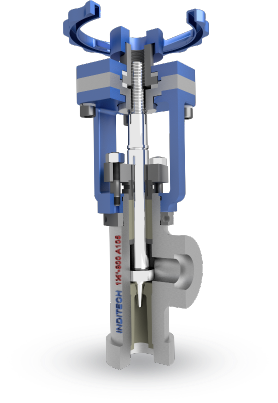

- Customised desuperheater designs are available for cases where ∆P between steam and water is very low.

- Completely customised to suit customer temperature parameters

- Easy installation & maintenance

- Field-proven with over 500 installations worldwide

- Multiple types of Desuperheaters are available to cater all process requirements–from low load fluctuations to high load fluctuations.

- Single-point contact vendor with complete package responsibility & guarantee

- Full support for piping layout design can be provided on request